Meru Jaya Pome Solutions at AIR 2040! It was an honor to showcase our solutions as part of Ensearch, with the event officiated by YAB Dato' Sri Haji Fadillah bin Haji Yusof, Deputy Prime Minister and Minister of Energy Transition and Water Transformation (PETRA). #ShapingTheFuture #EnergyInnovation

see moreMalaysia's Green Future is Here!

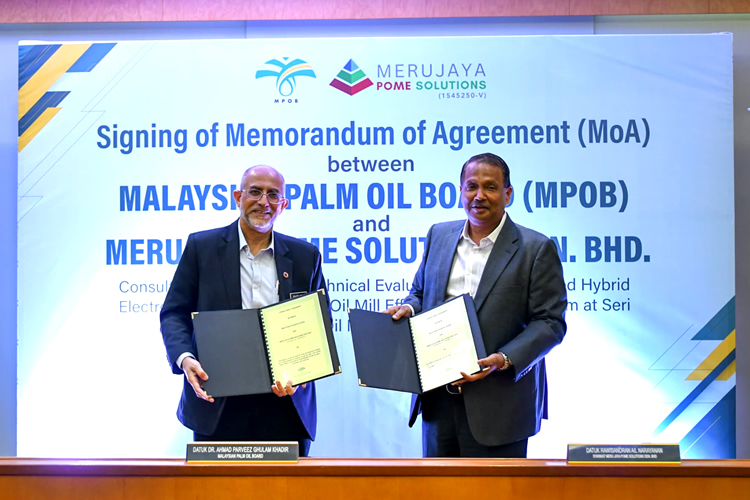

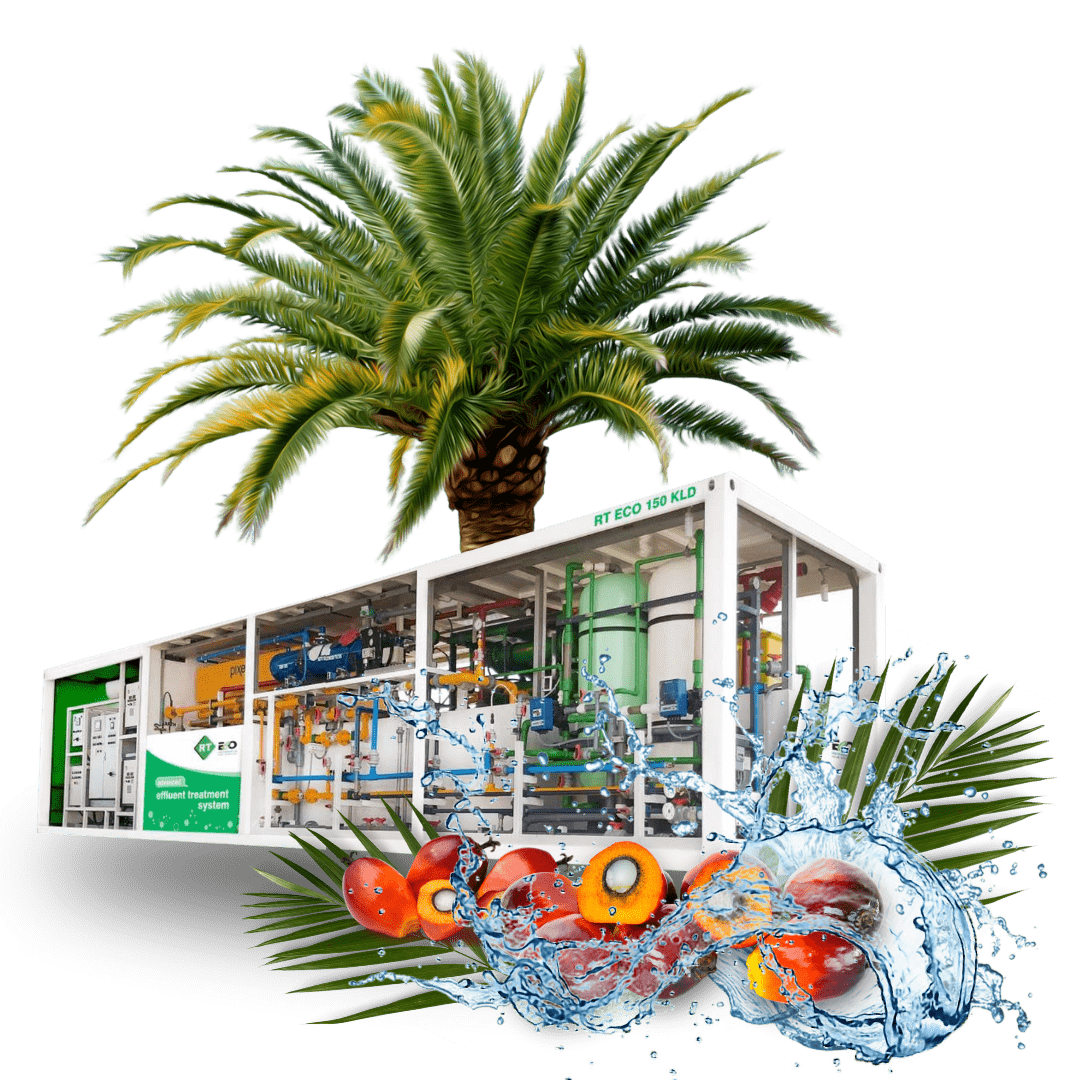

It’s with great excitement that we unveil Meru Jaya Pome Solutions has achieved validation by The Malaysian Palm Oil Board (MPOB) for our groundbreaking palm oil technology - RT ECO™, setting a new benchmark in green tech efficiency. Leading the way in sustainable innovation, we’re shaping a brighter, greener future for Malaysia and beyond.

#EcoMalaysia #CleanTech #POMERevolution

Why Choose Us

Discover the efficiency of Palm Oil Mill Effluent (POME) treatment systems

Palm oil mill effluent (POME) refers to wastewater generated from palm oil milling activities, requiring efficient treatment prior to discharge into watercourses due to its highly polluting nature.

Characterizing wastewater stands as a crucial initial phase in designing any wastewater treatment plant (WWTP) within the industry, given the time-consuming and costly nature of conducting pilot-scale tests to procure design and operational parameters.

Our Research Partners

Challenges in POME Management

One of the primary challenges faced by every Palm Oil Mill is how to handle its palm oil effluent waste. If not managed properly and seriously, it can damage the surrounding natural ecosystem. Several issues range from routine drainage, embankment landslides, leaking effluent ponds, high Biochemical Oxygen Demand (BOD), pond overflow, to the depletion of fish populations in rivers.

To address these challenges, the selection of appropriate waste treatment technology is crucial. By prioritizing environmental conservation in choosing and implementing more efficient waste treatment technologies, palm oil mills are expected to contribute to the preservation of the surrounding environment and support sustainable development.

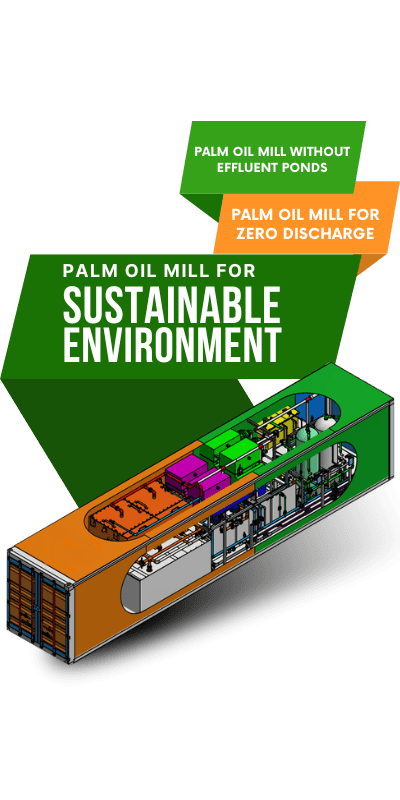

Cutting-edge, Eco-friendly Technology Advancement

Employing a compact, modular system for scalability

Simplifying operation and maintenance

Producing non-potable treated water for mill processing

Utilizing local technology without added chemicals

Reducing odor and GHG emissions by eliminating anaerobic ponds

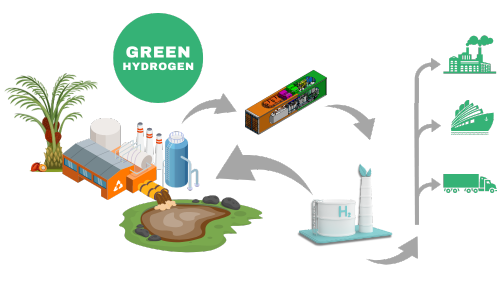

Embracing green hydrogen as an energy alternative

Salient Features RT ECO™

An innovative technological advancement in POME treatment with a focus on environmental sustainability

RT ECO™ Hybrid Advanced Wastewater Treatment System offers a cutting-edge solution for managing Palm Oil Mill Effluent (POME) sustainably. By integrating electro-coagulation and electro-oxidation cells, this green technology transforms POME into reusable water and solid fertilizer without the addition of chemicals.

Our hybrid electrochemical effluent treatment systems are designed with ESG principles in mind. They are fully automated, skid-mounted, and containerized, ensuring ease of installation and operation. Operating continuously, even in remote areas, these systems efficiently convert effluent into valuable resources, aligning with sustainability goals and promoting environmental stewardship.

RT ECO™ - Technology Using SCADA (RealTime) Monitoring System

By utilizing SCADA in palm oil effluent treatment, it is expected that the Mill will be able to automate and monitor effluent treatment processes more effectively. One of which allows operators to monitor and control various important parameters in real-time, such as temperature, pressure, pH, and noise levels, which affect the quality and efficiency of effluent treatment.

- Process Automation: By leveraging SCADA, mill can automate most of the effluent treatment processes. This reduces reliance on manual intervention, improves operational efficiency, and reduces the risk of human errors.

- Real-Time Monitoring: SCADA enables real-time process monitoring remotely. Operators can access up-to-date information about the operational conditions of the mill from anywhere, even from their mobile devices, enabling quick responses to condition changes

- Quick Problem Identification: With real-time monitoring capabilities, SCADA allows early detection of disturbances or anomalies in the effluent treatment process. This enables the operational team to identify problems quickly and take corrective action before they escalate.

- Performance Improvement: With the ability to monitor operational parameters in real-time, SCADA helps optimize mill performance. This includes reducing machine downtime, improving energy efficiency, and reducing effluent generation.

- Operational Safety: SCADA also plays a role in improving operational safety at the mill. By real-time monitoring critical parameters such as pressure and temperature, SCADA can detect potential hazards or equipment failures early, allowing appropriate preventive actions to be taken.

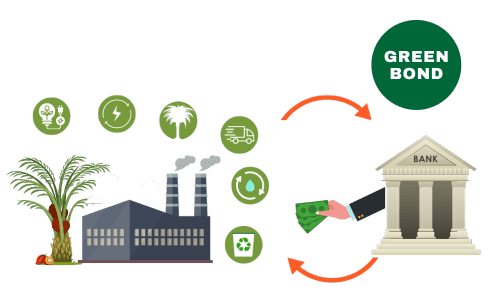

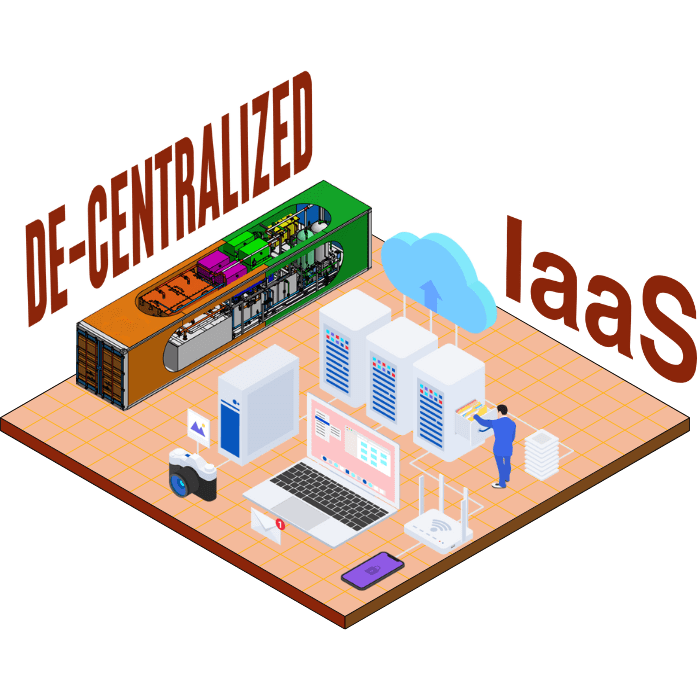

RT ECO™ - Effluent Treatment Technology with IaaS-Based System

Payment based on the volume of effluent processed allows companies to manage budgets more efficiently, avoid large upfront capital investments, and access the latest technology more quickly and flexibly.

Here are some comparisons between waste processing technology based on IaaS and the CapEx model:

| PARAMETER | RT ECO™ IaaS Model | Other CAPEX Model |

|---|---|---|

| Investment | We invest. | 100% by customer. |

| What You Pay For | Pay Per Liter of treated water, with no hidden costs. | Pay for everything including many unplanned & hidden costs. |

| Per Unit Saving | We offer Savings from day 1. | Dependent on technology, efficiency and vendor. |

| Technical Know How | We have the flexibility to adapt to any advancement in technology. | No scope for technological upgradation. |

| O&M | We bear all the expenses with no hidden cost. | Customer pays separately for all the cost. |

| Manpower Management | We offer skilled technicians from our resource pool. | Challenges in recruitment and retention of skilled manpower. |

| Regulatory Risk and Approvals | We ensure treated water quality, meeting all regulatory requirements. | Continuous challenges in meeting regulatory treated water quality. |

| Performance Risk | We bear all the performance risks with no hidden cost. | Client bears all the performance risks, associated hidden costs and direct costs |

Benefits of Utilizing our Technology

POME will be treated to separate WATER and SOLID

WATER can be reused by Palm Oil Mill

SOLID can be sold as animal feed or used as fertilizer

No need Wastewater Ponding

No need to Install Sparing Tools

Benefits of RT ECO™

By adapting Our Technology

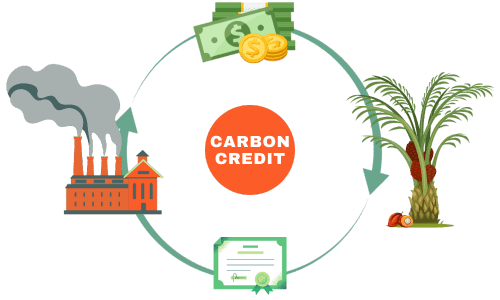

Our innovative POME (Palm Oil Mill Effluent) treatment technology, palm oil mills can significantly advance their sustainability initiatives.

This cutting-edge solution not only efficiently treats wastewater, reducing harmful environmental impacts, but also promotes the conservation of water resources through recycling and reuse processes.

RT ECO™ technology offers a comprehensive approach to environmental stewardship and sustainable industrial practices, supporting the palm oil industry's transition towards a more sustainable and responsible future.