What is RT ECO™ ?

* System design meeting explosion proof classification

* System design meeting explosion proof classification* Certification as per operation location / country

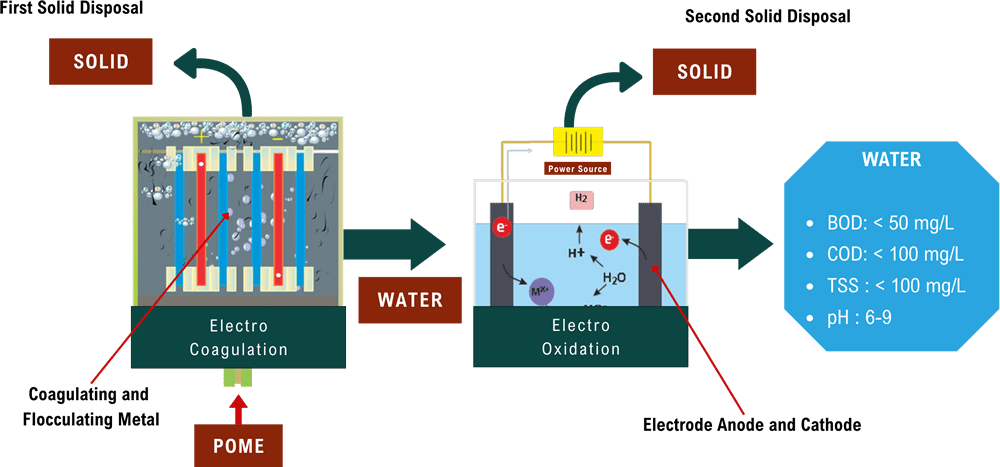

RT ECO™ Hybrid Advanced Wastewater Treatment System offers a cutting-edge solution for managing Palm Oil Mill Effluent (POME) sustainably. By integrating electro-coagulation and electro-oxidation cells, this green technology transforms POME into reusable water and solid fertilizer without the addition of chemicals.

Our hybrid electrochemical effluent treatment systems are designed with ESG principles in mind. They are fully automated, skid-mounted, and containerized, ensuring ease of installation and operation. Operating continuously, even in remote areas, these systems efficiently convert effluent into valuable resources, aligning with sustainability goals and promoting environmental stewardship.

Technology for a Sustainable Environment

MODEL & CAPACITY RT ECO™

| Model | Processing | Mill Capacity | POME (M3/HR) |

|---|---|---|---|

| POW - 0.6 MLD | 600 M3/Day (25 M3/Hr) | 30-33 TPH POM | POME = 33x60% 20 |

| POW - 1.2 MLD | 1200 M3/Day (50 M3/Hr) | 60-65 TPH POM | POME = 65x60% 42 |

| POW - 2.4 MLD | 2400 M3/Day (100 M3/Hr) | 90-130 TPH POM | POME = 130x60% 78 |

| POW - 3.6 MLD | 3600 M3/Day (150 M3/Hr) | 200 TPH POM | POME = 200x60% 120 |

| POW - 4.8 MLD | 4800 M3/Day (200 M3/Hr) | 265 TPH POM | POME = 265x60% 159 |

- Commanding a minimal footprint (1/8 of conventional systems)

- Engineered for seamless Plug and Play operation/installation

- Defying temperature extremes (10°C to 49°C)

- Demanding minimal Civil work

- Generating negligible sludge (less than 1/10 of conventional systems)

- Sludge that emerges pure, devoid of additional chemicals

- Low noise operations

- Odour-free system

Efficiency in Removing Unwanted Particles and Artifacts

The Advanced Hybrid Electro-Chemical technology effectively removes the following:

- Organics

- Suspended Solids

- Turbidity

- Algae

- Odour

- Colour

- Disinfect Water

- Fats, Oil & Grease

- Heavy Metals

Backed by Statistics and Data

Our mill effluent treatment system has undergone rigorous testing and analysis to ensure the maximum efficiency.

| Parameter | Unit | Raw Effluent | Treated Effluent | Standard |

|---|---|---|---|---|

| pH | 4-5 | 5-9 | 6-9 | |

| BOD | mg/L | ±25.000 | 50 | 100 |

| COD | mg/L | ±50.000 | 300 | 350 |

| O & G | mg/L | ±6.000 | 2 | 25 |

| TSS | mg/L | ±20.000 | 100 | 250 |

| Nitrogen Total (N) | mg/L | ±600 | 20 | 50 |

| Color | Dark Brownish | No Color | No Color | |

| Odour | Stinky | No Odour | No Odour |

Salient Features RT ECO™

An innovative technological advancement in POME treatment with a focus on environmental sustainability

RT ECO™ Hybrid Advanced Wastewater Treatment System offers a cutting-edge solution for managing Palm Oil Mill Effluent (POME) sustainably. By integrating electro-coagulation and electro-oxidation cells, this green technology transforms POME into reusable water and solid fertilizer without the addition of chemicals.

Our hybrid electrochemical effluent treatment systems are designed with ESG principles in mind. They are fully automated, skid-mounted, and containerized, ensuring ease of installation and operation. Operating continuously, even in remote areas, these systems efficiently convert effluent into valuable resources, aligning with sustainability goals and promoting environmental stewardship.

RT ECO™ - Technology Using SCADA (RealTime) Monitoring System

By utilizing SCADA in palm oil effluent treatment, it is expected that the Mill will be able to automate and monitor effluent treatment processes more effectively. One of which allows operators to monitor and control various important parameters in real-time, such as temperature, pressure, pH, and noise levels, which affect the quality and efficiency of effluent treatment.

- Process Automation: By leveraging SCADA, mill can automate most of the effluent treatment processes. This reduces reliance on manual intervention, improves operational efficiency, and reduces the risk of human errors.

- Real-Time Monitoring: SCADA enables real-time process monitoring remotely. Operators can access up-to-date information about the operational conditions of the mill from anywhere, even from their mobile devices, enabling quick responses to condition changes

- Quick Problem Identification: With real-time monitoring capabilities, SCADA allows early detection of disturbances or anomalies in the effluent treatment process. This enables the operational team to identify problems quickly and take corrective action before they escalate.

- Performance Improvement: With the ability to monitor operational parameters in real-time, SCADA helps optimize mill performance. This includes reducing machine downtime, improving energy efficiency, and reducing effluent generation.

- Operational Safety: SCADA also plays a role in improving operational safety at the mill. By real-time monitoring critical parameters such as pressure and temperature, SCADA can detect potential hazards or equipment failures early, allowing appropriate preventive actions to be taken.

RT ECO™ - Effluent Treatment Technology with IaaS-Based System

Payment based on the volume of effluent processed allows companies to manage budgets more efficiently, avoid large upfront capital investments, and access the latest technology more quickly and flexibly.

Here are some comparisons between waste processing technology based on IaaS and the CapEx model:

| PARAMETER | RT ECO™ IaaS Model | Other CAPEX Model |

|---|---|---|

| Investment | We invest. | 100% by customer. |

| What You Pay For | Pay Per Liter of treated water, with no hidden costs. | Pay for everything including many unplanned & hidden costs. |

| Per Unit Saving | We offer Savings from day 1. | Dependent on technology, efficiency and vendor. |

| Technical Know How | We have the flexibility to adapt to any advancement in technology. | No scope for technological upgradation. |

| O&M | We bear all the expenses with no hidden cost. | Customer pays separately for all the cost. |

| Manpower Management | We offer skilled technicians from our resource pool. | Challenges in recruitment and retention of skilled manpower. |

| Regulatory Risk and Approvals | We ensure treated water quality, meeting all regulatory requirements. | Continuous challenges in meeting regulatory treated water quality. |

| Performance Risk | We bear all the performance risks with no hidden cost. | Client bears all the performance risks, associated hidden costs and direct costs |

Cutting-edge, Eco-friendly Technology Advancement

Employing a compact, modular system for scalability

Simplifying operation and maintenance

Producing non-potable treated water for mill processing

Utilizing local technology without added chemicals

Reducing odor and GHG emissions by eliminating anaerobic ponds

Embracing green hydrogen as an energy alternative

Basic principles of RT ECO™

Process

Advanced Hybrid Electro-Chemical technology is a combination of 2 process :

- Electro-Coagulation

- Electro-Oxidation

The combination of this 2 reactors using specific metals is proven in managing the treatment of POME.

Technical Description